Mastering Soldering Copper Pipe Kits: A Comprehensive Guide

Share

Introduction

Soldering copper pipes is a valuable skill that can empower you to tackle various plumbing projects around your home, from fixing leaks to installing new fixtures. This comprehensive guide will take you through the essential steps and tips for mastering the art of soldering copper pipe kits. Whether you're a seasoned DIY enthusiast or just getting started with plumbing, this article will equip you with the knowledge and confidence to complete your projects successfully.

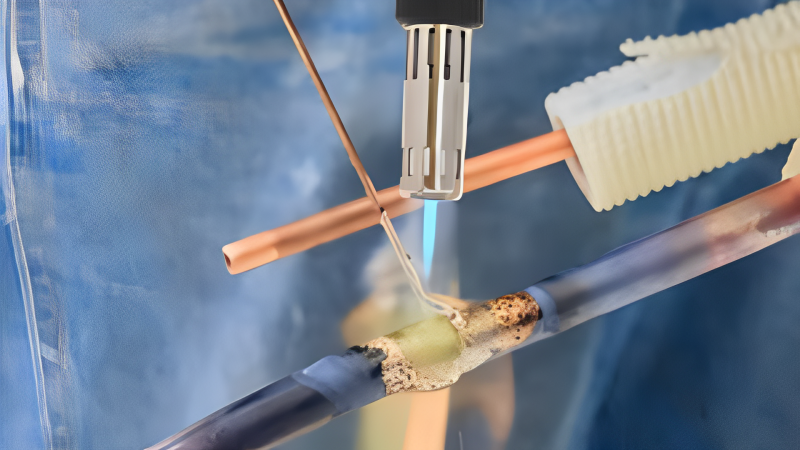

Quick Tips for Soldering Copper Pipes

Before we dive into the nitty-gritty details, here are some quick tips to keep in mind:

- Safety First: Always wear safety gear, including gloves and safety glasses, to protect yourself from burns and harmful chemicals in flux.

- Proper Ventilation: Ensure you're working in a well-ventilated area or use an exhaust fan when soldering to avoid inhaling fumes.

- Clean Surfaces: Clean and prepare the copper pipe surfaces before soldering. Clean pipes result in solid and leak-free joints.

- Practice on Scrap: If you're new to soldering, practice on scrap pieces of copper pipe to hone your skills before working on your project.

- Consistent Heat: Maintain a steady, consistent heat when soldering to prevent overheating and damaging the pipe.

Now, let's delve into the full details of soldering copper pipes.

Understanding Copper Pipes

Types of Copper Pipes

Copper pipes come in various styles, each suited to different applications:

- Type M: Thin-walled and cost-effective, suitable for low-pressure applications like residential plumbing.

- Type L: Medium-walled, balancing cost and durability. They are used in both residential and commercial plumbing.

- Type K: Thick-walled and highly durable, suitable for high-pressure applications like underground water mains.

Typical Applications for Copper Pipes

Copper pipes are commonly used in plumbing for:

- Supplying hot and cold water

- Transporting natural gas

- Radiant heating systems

- Refrigeration lines

- Fire sprinkler systems

Advantages of Using Copper Pipes

Copper pipes offer several advantages:

- Durability: Copper is corrosion-resistant and can last for decades.

- Heat Tolerance: Copper can handle high temperatures without degradation.

- Safety: Copper is non-toxic and won't release harmful substances into your water supply.

- Ease of Installation: Copper pipes are relatively easy to work with, especially when soldering.

Precautions When Working with Copper

- Be mindful of copper's thermal conductivity; it can boil during soldering.

- Ensure proper support for pipes to prevent stress and leaks.

- Avoid direct contact between copper pipes and electrical wiring.

Essential Tools and Materials

Before you start soldering copper pipes, gather the necessary tools and materials:

- Soldering Iron or Torch: A soldering iron or torch provides the heat needed to melt solder.

- Flux and Solder: Flux is essential for cleaning and preparing the pipe surfaces, while solder creates a strong joint.

- Pipe Cutter: Use a pipe cutter to cut copper pipes cleanly and accurately.

- Sandpaper and Cleaning Brush: These tools are for cleaning the pipe ends, ensuring a smooth surface for soldering.

- Safety Gear: Invest in safety gear such as gloves and safety glasses to protect yourself during soldering.

Preparing the Workspace

A well-prepared workspace is crucial for a successful soldering project. Here's what you need to do:

Safety Precautions

Safety should be your top priority when soldering copper pipes:

- Keep a fire extinguisher nearby.

- Ensure your workspace is free from flammable materials.

- Avoid loose-fitting clothing that can catch fire.

Proper Ventilation

Set up your workspace in a well-ventilated area, preferably near an open window or with an exhaust fan. Soldering produces fumes that you should avoid inhaling.

Organizing Tools and Materials

Arrange your tools and materials within easy reach to prevent unnecessary movement during the soldering process. This will help you maintain focus and control over your work.

Cleaning the Copper Pipes

Properly clean the pipe ends using sandpaper or a cleaning brush. This step is crucial for removing oxidation and ensuring a solid bond when soldering.

Marking and Measuring

Measure and mark the pipe lengths accurately before cutting. Proper measurements help ensure that your pipes fit together perfectly.

Steps for Soldering Copper Pipes

Now that your workspace is ready let's go through the step-by-step process of soldering copper pipes:

1. Cutting and Fitting the Pipes

- Measure and mark the pipes for the desired length.

- Use a pipe cutter to make a clean, square cut.

- Ensure the pipes fit snugly into fittings and connectors.

2. Applying Flux to Clean Surfaces

- Apply flux to the cleaned pipe ends and the inside of the fittings.

- Flux cleans the surfaces and helps solder flow evenly.

3. Assembling and Positioning the Pipes

- Insert the pipes into the fittings and connectors.

- Ensure they are correctly aligned and seated.

4. Heating the Joint with a Soldering Iron/Torch

- Heat the joint evenly using a soldering iron or torch.

- Move the heat source around the joint to distribute heat uniformly.

5. Applying Solder to the Joint

- When the joint is hot enough, touch the solder to the seam.

- Solder should melt and flow smoothly into the joint by capillary action.

6. Cooling and Inspecting the Soldered Joint

- Allow the joint to cool naturally.

- Inspect the joint for a smooth, even, and shiny solder finish.

7. Repeat for Additional Connections

Repeat the above steps for each joint if your project involves multiple connections.

Troubleshooting Common Issues

Despite your best efforts, you may encounter some common soldering issues. Here's how to troubleshoot them:

Dripping or Uneven Solder Joints

- Ensure the joint is clean and adequately fluxed.

- Maintain a consistent heat source and soldering technique.

Overheating and Damaging the Pipe

- Avoid excessive heating; copper can become damaged if it gets too hot.

- Practice your technique on scrap pieces before working on critical joints.

Proper Soldering Technique

- Learn the proper technique for soldering, including heating and applying solder.

Dealing with Leaks

- If you experience leaks, identify the source and re-solder the joint if necessary.

- Use pipe compound or joint filler for stubborn leaks.

Tips for Success

Mastering soldering copper pipes takes practice and patience. Here are some additional tips for success:

Maintaining a Steady Hand

Soldering requires a steady hand, so take your time to avoid mistakes.

Practice on Scrap Pieces

If you're new to soldering, practice on scrap pieces of copper pipe to build your skills.

Consistent Heating and Soldering Technique

Consistency is vital; maintain the same heating and soldering technique for all joints.

Ensuring Leak-Proof Joints

Leakage can be costly; always ensure your joints are tight and sealed.

Safety Reminders

Don't overlook safety precautions; soldering can be hazardous if not done correctly.

Cleaning and Finishing

Once you've completed your soldering project, follow these steps to clean and finish your work:

Removing Excess Flux

- Use a damp cloth or sponge to remove excess flux.

- Clean the area around the joints.

Wiping Down the Pipes

- Wipe down the pipes to remove any residue or fingerprints.

Inspecting the Entire System

- Inspect the entire system for any signs of leaks or issues.

- Address any problems promptly to prevent future damage.

Table of Soldering Copper Pipe Kit Supplies

|

Product |

Description |

Price (Approx.) |

| Berkling BSG-2000 | High heat output and multi-functional. Can be used as soldering iron and heat gun. | $95.00 |

|

High-intensity torch for soldering |

$49.97 |

|

|

High-quality flux for cleaning surfaces |

$4.49 |

|

|

Lead-free solder for solid joints |

$12.98 |

|

|

Fast and clean pipe-cutting tool |

$31.42 |

|

|

Deburring tool for smooth edges |

$22.99 |

|

|

Safety glasses for eye protection |

$11.87 |

|

|

PVC-coated gloves for hand protection |

$12.99 |

Please note that prices may vary based on location and seller. Make sure to choose the right products for your specific project needs.

Conclusion

Soldering copper pipes is a valuable skill that can save you time and money on plumbing projects. You can confidently tackle various plumbing tasks by following the steps outlined in this comprehensive guide and adhering to safety precautions. Remember to practice, be patient, and prioritize safety. With the proper knowledge and techniques, you'll be well on your way to mastering soldering copper pipe kits.